Tapping into Untapped Potential

Have you ever thought about the sheer amount of energy that goes to waste every day? I mean, think about it – we have all these appliances, devices, and systems that generate heat as a byproduct, and for the most part, we just let that heat dissipate into the atmosphere. What a missed opportunity, right? Well, my friends, that’s where thermoelectric generators come into play, and I’m about to show you how you can build your very own DIY version to harness that wasted heat.

Understanding Thermoelectrics

Before we dive into the DIY part, let’s take a quick detour and explore the science behind thermoelectric generators. At their core, these devices rely on the Seebeck effect, which was discovered way back in 1821 by the German physicist Thomas Johann Seebeck. The Seebeck effect states that when two dissimilar metals or semiconductors are joined and one junction is kept at a higher temperature than the other, a voltage is generated. This voltage can then be used to power an electrical device or be stored in a battery for later use.

The key components of a thermoelectric generator are the thermoelectric material and the heat sink. The thermoelectric material, typically made from semiconductor alloys like bismuth telluride or lead telluride, is responsible for converting the heat into electricity. The heat sink, on the other hand, helps to maintain the temperature difference between the hot and cold junctions, which is essential for the Seebeck effect to occur.

One of the main advantages of thermoelectric generators is their simplicity and reliability. They have no moving parts, which means they require minimal maintenance and have a long lifespan. Additionally, they can be used in a wide range of applications, from powering small electronic devices to generating electricity in remote or off-grid locations.

Harnessing Waste Heat

Now, let’s talk about how we can put this technology to work and build our own DIY thermoelectric generator to recover waste heat. The key is to identify sources of waste heat in our homes, workplaces, or even our vehicles. Researchers have found that even small-scale applications, like recovering waste heat from a laptop or a coffee maker, can generate significant amounts of electricity to power various devices or charge batteries.

One excellent source of waste heat is the exhaust system of a vehicle. As the hot exhaust gases pass through the tailpipe, a significant amount of energy is simply released into the air. By installing a thermoelectric generator on the exhaust system, we can capture that heat and convert it into usable electricity to power the vehicle’s electrical systems or charge a battery.

Another promising application is recovering waste heat from industrial processes. Many industrial facilities, such as power plants, manufacturing plants, and refineries, generate vast amounts of waste heat that could be harnessed using thermoelectric generators. This not only reduces the overall energy consumption of the facility but also helps to improve its environmental footprint.

Building Your DIY Thermoelectric Generator

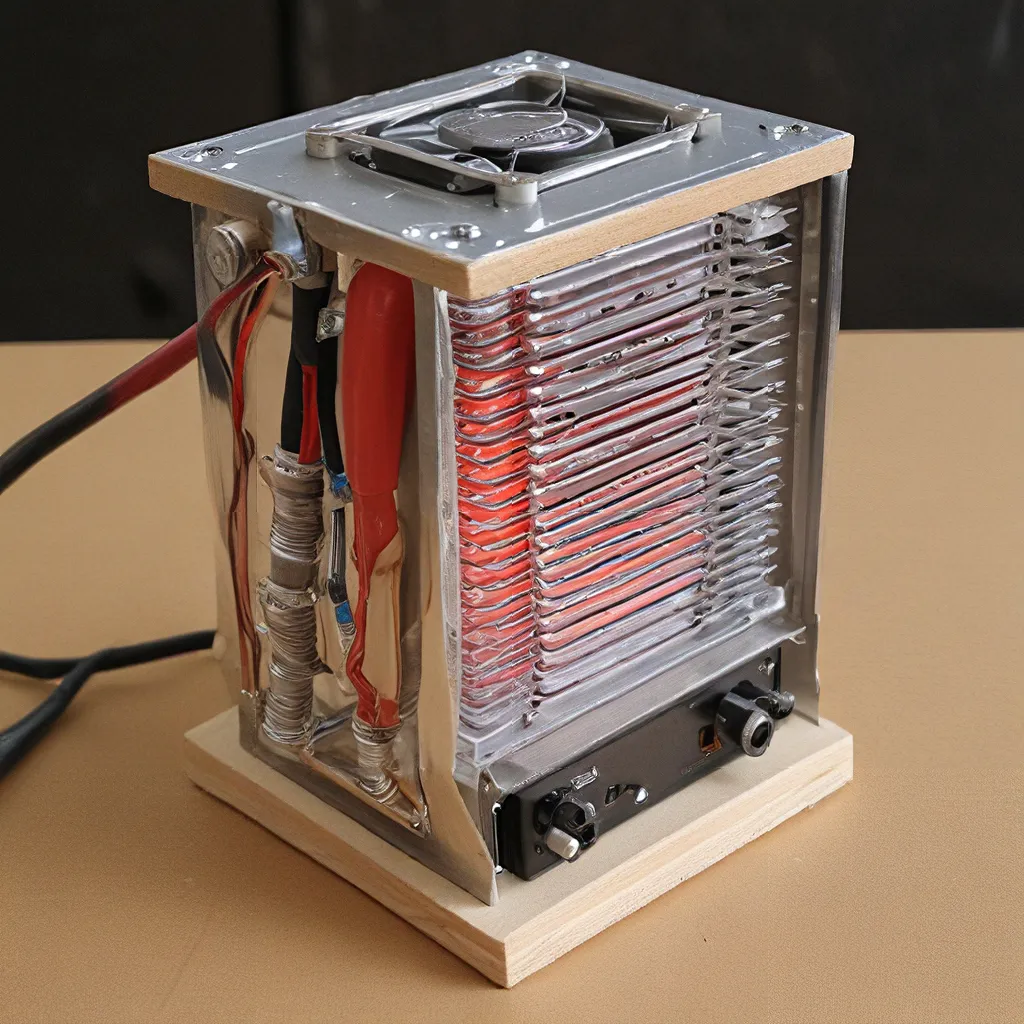

Alright, let’s get to the fun part – building your very own DIY thermoelectric generator! This project is relatively straightforward and can be done with materials readily available at your local hardware store or online. Here’s what you’ll need:

- Thermoelectric modules: These are the core components that convert the heat into electricity. You can find them on sites like Plug ‘n’ Save Energy Products or at your local electronics store.

- Heat sink: This component helps to maintain the temperature difference between the hot and cold junctions. You can use a standard CPU heat sink or even a piece of metal with fins.

- Insulation: To prevent heat loss and maintain the temperature difference, you’ll need some kind of insulation material, such as foam or fiberglass.

- Wiring and connectors: You’ll need some basic electrical components like wires, a voltmeter, and a load (e.g., a light bulb or a small electronics device) to complete the circuit.

The assembly process is fairly straightforward:

- Prepare the heat sink: Attach the thermoelectric module to the heat sink, making sure to apply a thin layer of thermal paste between the two surfaces to improve heat transfer.

- Insulate the setup: Surround the heat sink and module with the insulation material to minimize heat loss and maintain the temperature difference.

- Connect the electrical components: Wire the thermoelectric module to the voltmeter and the load, ensuring a proper circuit.

- Test and optimize: Place the setup on a heat source, such as a hot plate or the exhaust of a running vehicle, and observe the voltage and power output. Experiment with different configurations and materials to maximize the efficiency of your DIY thermoelectric generator.

The beauty of this project is that you can scale it up or down depending on your needs and the available heat sources. You could start with a small setup to power a LED light or a USB charger, and then gradually expand it to capture more waste heat and generate more electricity.

Powering the Future with Renewable Resourcefulness

As you can see, thermoelectric generators are a versatile and practical way to harness the power of waste heat and turn it into renewable energy. By building your own DIY version, you’re not only saving money on your energy bills but also contributing to a more sustainable future.

So, what are you waiting for? Grab your tools, find a source of waste heat, and let’s get started on your very own Renewable Resourcefulness project! Who knows, you might just end up powering your whole house with the heat from your oven or your car’s exhaust. The possibilities are endless, and the only limit is your creativity and resourcefulness.